In the realm of flexible packaging, the harmony between film structure and machinery is paramount. This case study delves into two real-world scenarios where misalignment between these components led to significant challenges. By examining these instances, we highlight the critical importance of integrated decision-making in packaging processes.

Company A:

Company B:

Company A:

Company B:

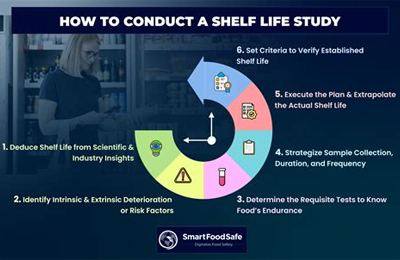

Steps involved in conducting a comprehensive shelf life study to ensure packaging suitability.

These cases underscore the necessity of a holistic approach in flexible packaging, where film selection and machinery compatibility are evaluated in tandem. Organizations must foster collaboration between procurement, operations, and technical teams to ensure product integrity and successful market delivery.

By aligning technical specifications with strategic procurement, companies can enhance product quality, reduce waste, and maintain brand reputation in the competitive landscape of flexible packaging.

Ready to optimize your packaging operations?

Learn more about Raas IntelliBox at www.raaasintelli.comCopyright © 2025 All Rights Reserved By RAAS INTELLI SOLUTIONS | Design and Developed By Arsh Infosystems